FEMKUBER ENGINEERING

We are a small and passionate Oslo, Norway-based engineering company built on values of quality, integrity and dependability.

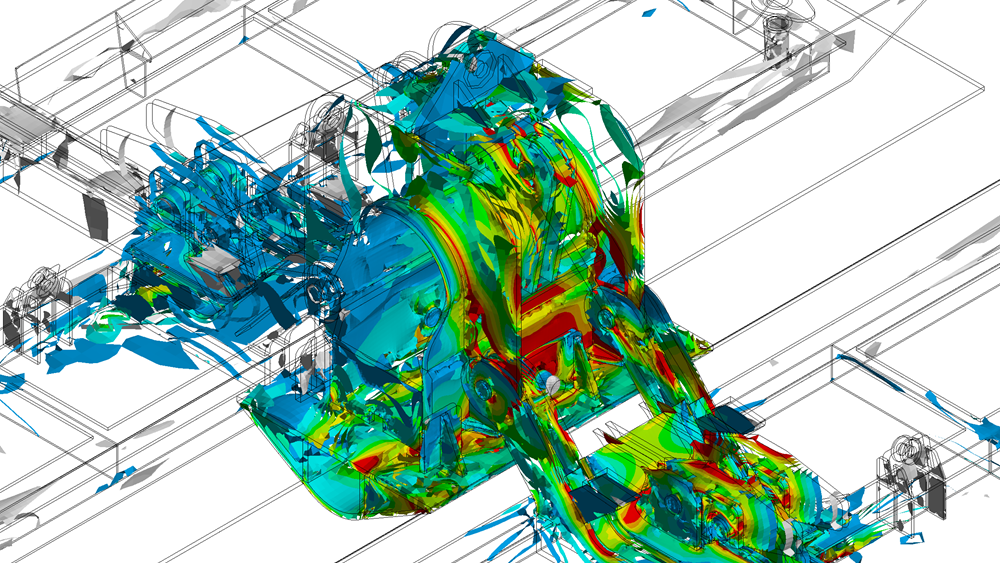

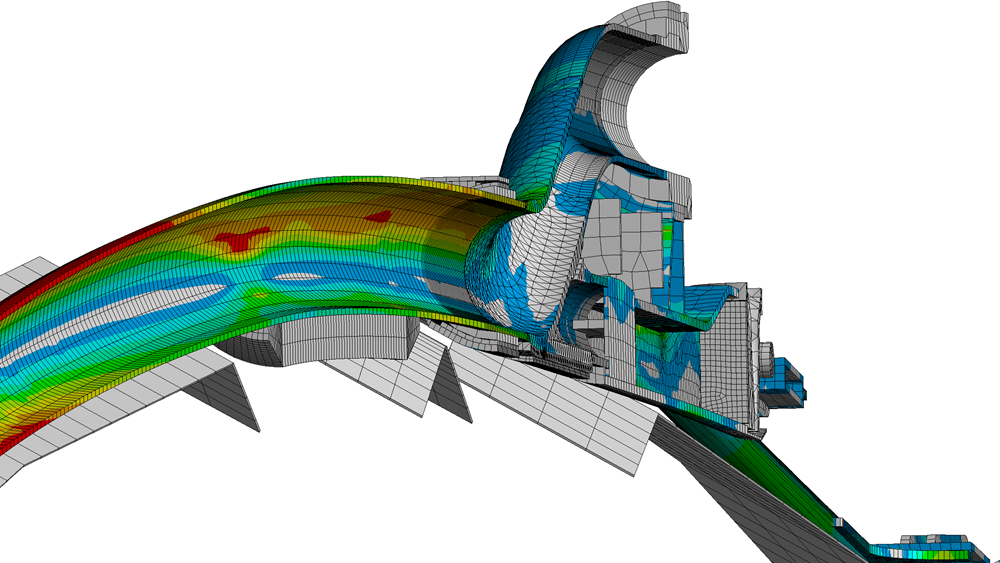

Reliability is the key to the abyss

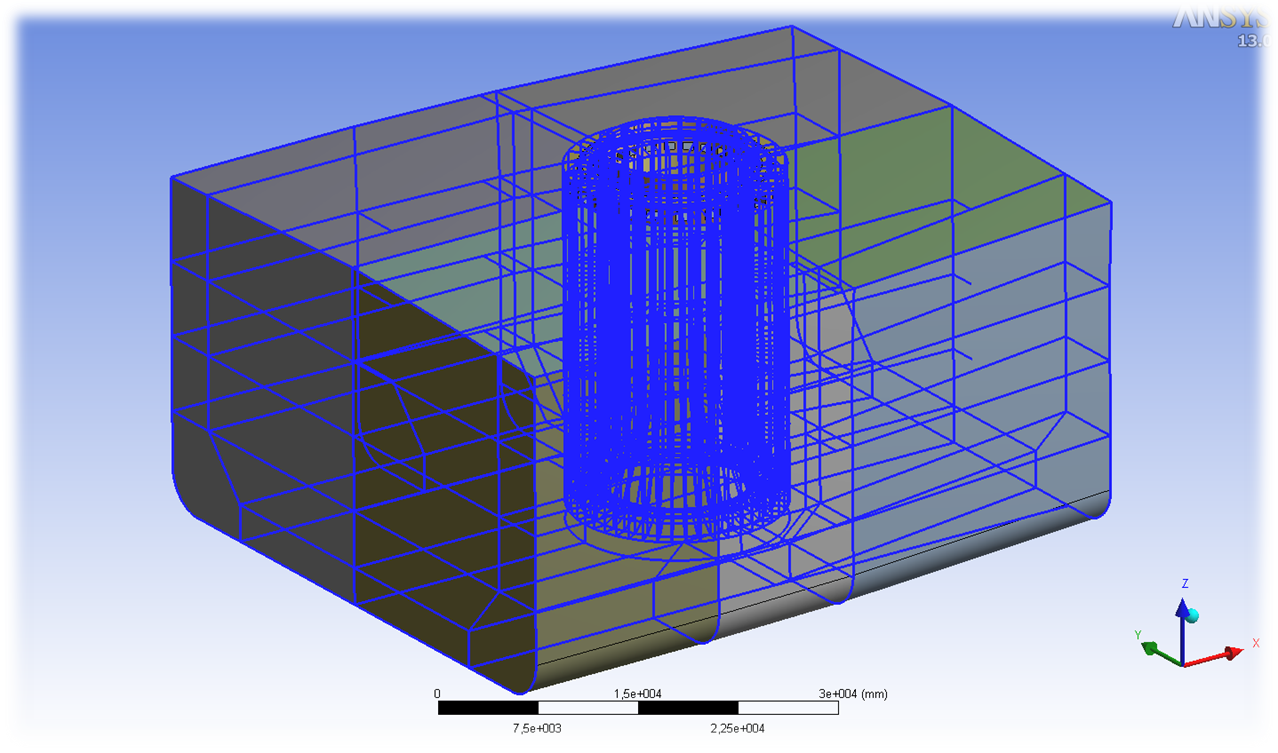

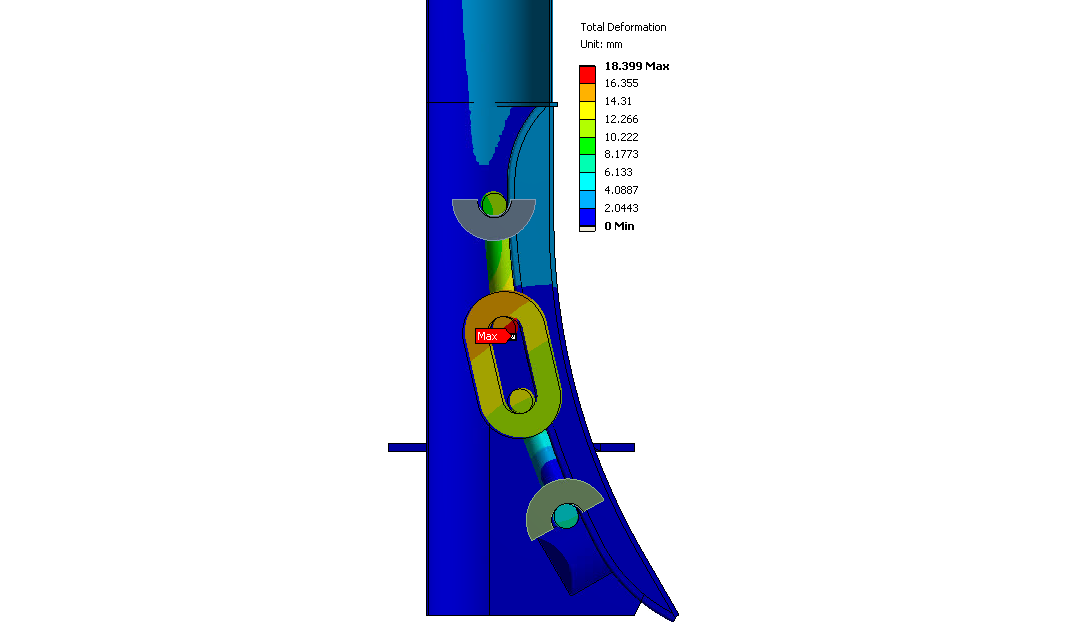

Endurance and reliability is of paramount importance in the subsea industry. Due to extreme pressures and temperatures, a highly corrosive environment, seismic activity and inaccessability in addition to human, economic and environmental risks, the engineering quality of subsea structures must be impeccable.

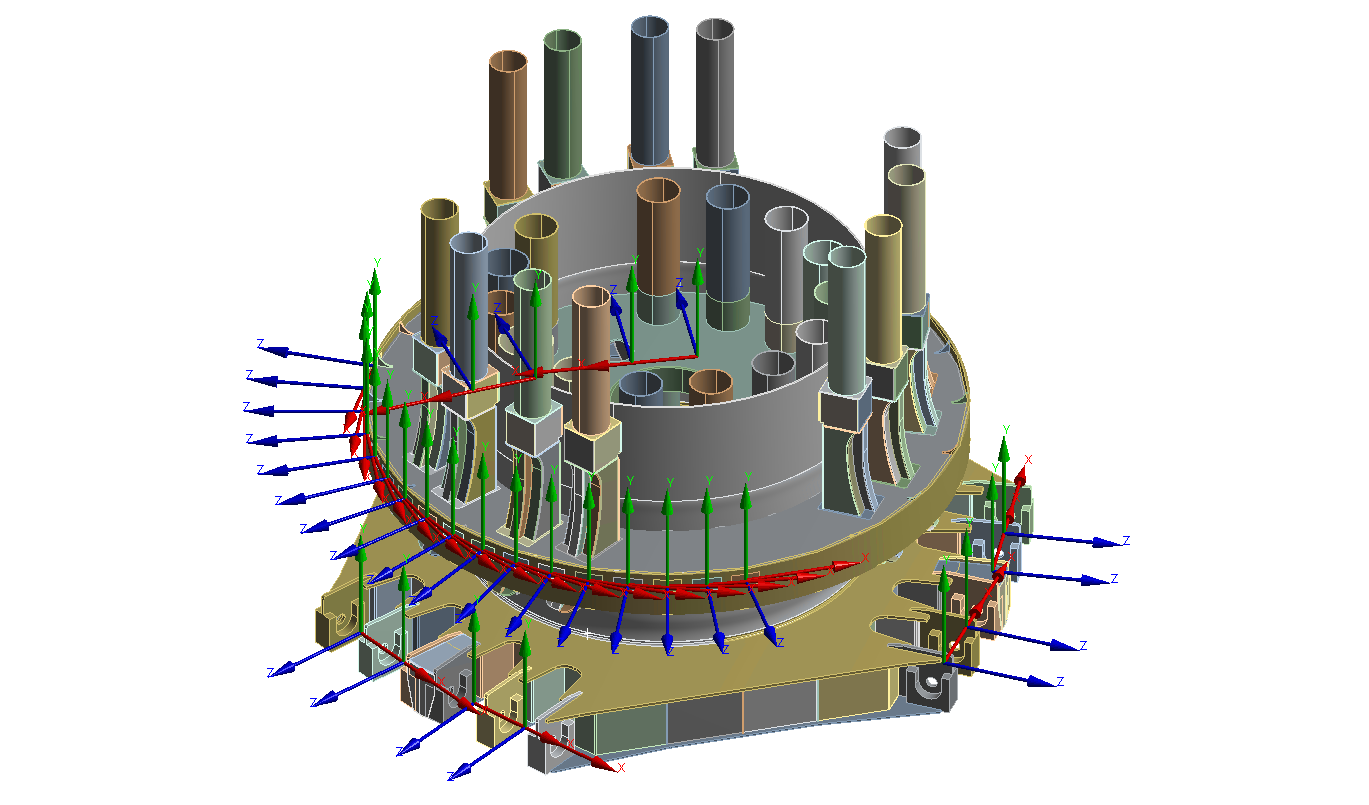

We have extensive experience in the subsea industry, performing simulations and aiding the design of subsea structures and components like spools/jumpers, pipelines, pressure vessels, fittings, in-line Tees and Wyes, PLEMs, PLETs and manifolds.

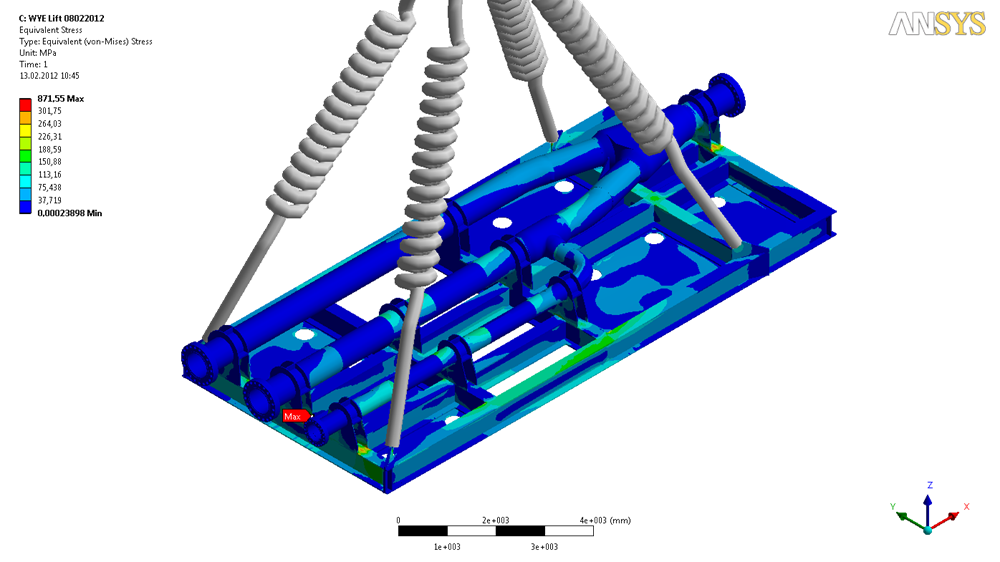

Designing for harsh environments

In many cases offshore structures involve human presence and interaction in a harsh and hostile environment. Here too, the focus on detail in functionality and quality is of utmost importance.

Femkuber has been involved in an large number of marine operations and holds long experience in structural and mechanical design and analyses of load carrying structures. Typical components Femkuber has been responsible for are lifting equipment, sea-fastening, deck and hull structures.